ESD Electrically Conductive Silicone Rubber Sheet

Thickness 1-2-3-4-5-6-7-8-9-10-12-15-20mm.etc

Width 0.5-1meter

Length 1-10meters

Custom size available

- Description

An Electronic Conductive Silicone Sponge Sheet is a specialized elastomeric material engineered to provide both electrical conductivity and environmental sealing in a soft, compressible form. It combines the flexible, durable properties of silicone rubber with the electrical properties of conductive fillers, all within a sponge (foam) structure.

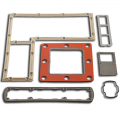

Electrically Conductive Silicone Sponge Rubber Roll and Sheet Gaskets Static Dissapative Application - Protection (cover) of Electronic Devices from Static Electricity and Temperature

| SPECIFICATION SHEET | |||

| Electrically Conductive Silicone Sponge Sheet | |||

| 1. DIMENSIONS AND APPEARANCE | |||

| Thickness | mm | 1-2-3-4-5-6-8-10mm custom thicknesses available | |

| Typical length | meter | 1-10, custom length available | |

| Typical width | meter | 0.5-1, custom width available | |

| Surface finishing | Textile finish both sides | ||

| Color | Black | ||

| 2. PHYSICAL PROPERTIES, TYPICAL | |||

| Hardness | Shore A | 10-15-20-25-30 | ASTM D2240 |

| Tensile strength | psi | 900 | ASTM D412 |

| Elongation | % | 200 | ASTM D412 |

| Volume resistivity | ohms/sqM | 10^6 to 10^11 ohms/sq | ASTM D991 |

| Low working temp | ℃ | -50 | |

| High working temp | ℃ | 205 | |

Moonus closed cell silicone sponge sheet is available in a wide range of densities from soft to extra-firm . Medium density closed cell silicone sponge customized thickness from 0.8mm(1/32'') to 50.8mm(2″),max width 1220mm(48''). This material has an excellent physical properties. both UV and ozone resistance, wide operating temperature from -40 Celsius to 250 Celsius. The closed cell structure allows for good water sealing with relatively low compressive forces, excellent compression set resistance especially at higher temperatures.

In addition, Moonus offer silicone sponge sheet in rolls and cut sheets (with/without PSA Adhesive) for convenient converting and fabricating.

Key Benefits of Closed Cell Silicone Sponge

Wide operating temperature – silicone sponge has a temperature range of -40C to 250C

Water sealing – the closed cell structure allows for good water sealing with relatively low compressive forces.

Compression set resistance – silicone offers excellent compression set resistance (ability to rebound to original thickness), especially at higher temperatures, compared to most rubber material. Low compression set silicone sponges are available for even better performance than general purpose grades.

UV and ozone resistance – silicone products have excellent UV and ozone resistance due in part to their organic backbone. This provides long term performance.

English

English

Russian

Russian